Every year, industries dump over 150 million tons of calcium carbonate waste into landfills, rivers, and quarries. Most of it comes from paper mills, steel plants, and water treatment facilities. It’s not toxic. It’s not flashy. But that doesn’t mean it’s harmless. The real problem isn’t what calcium carbonate waste is - it’s what we do with it, and how little we think about the consequences.

What Is Calcium Carbonate Waste?

Calcium carbonate (CaCO₃) is one of the most common minerals on Earth. You find it in limestone, chalk, marble, and even in your antacids. But when industries use it - like in flue gas desulfurization at power plants or as a filler in paper production - they generate massive amounts of leftover sludge. This waste is mostly pure calcium carbonate mixed with traces of heavy metals, salts, and organic residues. It’s often called calcium carbonate waste, but you’ll also hear it called gypsum sludge, scrubber residue, or white sludge.

In Australia alone, paper and pulp mills produce over 2 million tons of this waste annually. Most of it ends up in unlined landfills or dumped into old mining pits. It looks harmless - white, powdery, almost like snow. But appearance lies.

Soil Contamination and pH Imbalance

When calcium carbonate waste leaches into the ground, it doesn’t just sit there. It raises soil pH. A lot. In natural conditions, most Australian soils are slightly acidic - perfect for native plants like eucalyptus and banksia. But when you dump tons of calcium carbonate on them, the pH can jump from 5.5 to over 8.5 in just a few years.

That’s not a small change. It’s like pouring baking soda into a rainforest. Nutrients like iron, manganese, and phosphorus become locked up. Plants can’t absorb them. Roots suffocate. Microbes die off. In the Darling Downs region, farmers near a major paper mill reported a 60% drop in crop yields after five years of nearby waste dumping. The soil didn’t turn bad overnight - it turned silent.

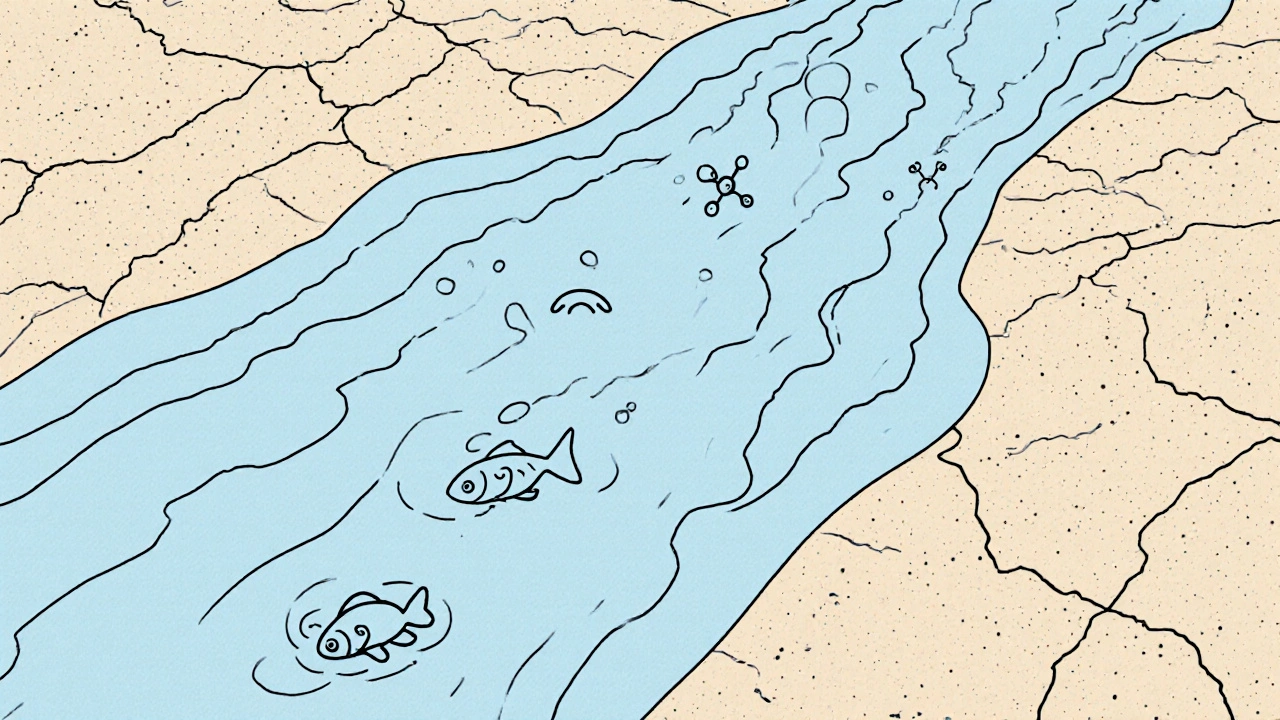

Water Pollution: Hidden Toxicity

Even though calcium carbonate itself is non-toxic, the waste isn’t pure. It’s a mix. In coal-fired power plants, flue gas scrubbers capture sulfur dioxide using limestone slurry. The leftover sludge contains traces of mercury, arsenic, lead, and selenium - all concentrated during the process.

When this waste is stored in open ponds or dumped near rivers, rainwater washes those metals into groundwater. In Queensland, testing near a former industrial site showed mercury levels in nearby bore water at 0.8 micrograms per liter - above Australia’s drinking water guideline of 0.6. It’s not a disaster level. But it’s persistent. And it builds up.

Fish in nearby streams started showing abnormal behavior. Liver damage. Reduced reproduction. No one called it poisoning. They called it “unexplained decline.”

Carbon Footprint of Disposal

Here’s the irony: calcium carbonate is a carbon sink. When it forms naturally, it locks away CO₂. But when we mine limestone, crush it, transport it, and then dump the waste, we’re releasing more carbon than we ever captured.

Producing one ton of calcium carbonate waste requires about 150 kg of CO₂ emissions from mining, grinding, and hauling. Multiply that by 150 million tons globally - that’s 22.5 million tons of CO₂ each year, just to dispose of something we could be reusing.

And landfilling it? That’s not the end. Organic matter trapped in the sludge slowly breaks down, releasing methane. A 2023 study in the Journal of Industrial Ecology found that calcium carbonate waste landfills in Southeast Asia emitted more methane per ton than some municipal landfills.

What Are the Alternatives?

Disposal isn’t the only option. It’s just the cheapest. And the dumbest.

- Construction aggregate: Clean calcium carbonate waste can replace crushed rock in road bases and concrete. In Europe, over 40% of scrubber residue is now used in cement production.

- Soil amendment: In acidic soils, a controlled application of purified calcium carbonate can actually help - but only if you know the exact pH and don’t overdo it. Farmers in Victoria are testing this with lab-tested waste from water treatment plants.

- Carbon capture: Some startups are turning calcium carbonate waste into synthetic limestone that can absorb CO₂ again. It’s early, but a pilot project in South Australia captured 12 tons of CO₂ per ton of waste processed.

- Recycling in paper mills: Closed-loop systems now exist where waste is reprocessed into filler for new paper. One mill in New South Wales cut its raw limestone purchases by 70%.

The problem isn’t technology. It’s regulation. Most countries still classify calcium carbonate waste as “non-hazardous.” That means no permits needed. No monitoring. No accountability. Just dump it and forget it.

Who’s Doing It Right?

Sweden banned landfilling of calcium carbonate waste in 2018. Now, all industrial waste must be reused or treated. Result? Landfill use dropped by 85%. The country now runs a thriving market for recycled carbonate products.

In Japan, paper mills sell their waste to brick manufacturers. The waste acts as a flux agent, reducing energy use in kilns by 18%. That’s not just waste management - that’s circular economy.

Australia has the resources, the tech, and the land. But we still treat this waste like trash. Not because we have to - but because we haven’t been forced to change.

What Can Be Done?

If you work in manufacturing, mining, or waste management: audit your calcium carbonate waste stream. Test it. Don’t assume it’s safe. Find out what’s in it. Then find a use.

If you’re a policymaker: update environmental regulations. Classify this waste based on actual composition, not just its main ingredient. Require reuse targets. Incentivize recycling.

If you’re a citizen: ask your local council where their industrial waste goes. Demand transparency. Support companies that recycle. Pressure regulators to act.

Calcium carbonate waste isn’t going away. We’re making more of it every year. The question isn’t whether we can stop it. It’s whether we’ll choose to treat it like a resource - or keep pretending it’s just dirt.

Is calcium carbonate waste dangerous to human health?

Direct contact with pure calcium carbonate waste isn’t toxic - it’s used in food and medicine. But industrial waste often contains traces of heavy metals like mercury or arsenic from the production process. Inhaling fine dust over long periods can irritate lungs, and contaminated groundwater can lead to long-term exposure risks. Testing the specific waste stream is essential.

Can calcium carbonate waste be recycled?

Yes, and it already is in many countries. Clean, uncontaminated waste can be used as construction aggregate, in cement production, as a soil amendment in acidic areas, or even as a raw material for synthetic limestone in carbon capture systems. The key is purification and regulation - not dumping.

Why isn’t calcium carbonate waste regulated like hazardous waste?

Because regulators focus on the main component - calcium carbonate - and ignore trace contaminants. It’s classified as non-hazardous based on outdated guidelines. But modern testing shows many waste streams contain harmful levels of heavy metals. This gap in regulation is why so much ends up in landfills without proper monitoring.

How does calcium carbonate waste affect local ecosystems?

It alters soil pH, making it too alkaline for native plants and soil microbes. It can leach heavy metals into groundwater, affecting aquatic life. In Australia, studies have shown reduced biodiversity in streams near dumping sites. The damage is slow, but it’s cumulative - and often irreversible without intervention.

What are the biggest sources of calcium carbonate waste?

The top sources are flue gas desulfurization in coal-fired power plants, paper and pulp mills using limestone as a filler, and water treatment facilities using lime to soften water. In Australia, paper mills and power plants account for over 80% of total waste volume.

Alex Hundert

October 31, 2025 AT 22:49This isn't just an environmental issue-it's a systemic failure of regulation. We treat calcium carbonate waste like it's harmless because it's white and powdery, but we're ignoring the cocktail of heavy metals it carries. The fact that it's not classified as hazardous is a joke. If it were lead or cadmium, we'd be shutting down plants. But because it's 'just calcium,' we dump it and call it a day. That's not science-it's negligence.

Emily Kidd

November 2, 2025 AT 05:58my friend works at a paper mill in oregon and they’ve been reusing their sludge as filler for new paper for 3 years now. cut their limestone buyin by like 70% and saved a ton of cash. why isn’t this everywhere??

it’s not hard. just needs someone to care enough to change the process.

Justin Cheah

November 2, 2025 AT 20:26you think this is bad wait till you find out the government’s been using this waste in road construction since 2015 and no one’s testing the runoff

they call it ‘non-hazardous’ because if they admitted the truth the whole system collapses

mercury in your concrete driveways? oh no not again

the EPA knows. they’ve been told. but they’re scared to admit it because then they’d have to shut down half the power grid and who wants that right? corporations pay for the reports that say it’s safe. it’s all a scam. you’re being lied to every time you hear ‘non-toxic’

MOLLY SURNO

November 3, 2025 AT 06:10I appreciate how thoroughly this was laid out. It’s easy to overlook waste that doesn’t smell or glow, but the quiet destruction-soil turning silent, fish behaving oddly, groundwater creeping upward with toxins-it’s the most insidious kind of pollution. We need more awareness like this, not just outrage.

caiden gilbert

November 4, 2025 AT 14:31it’s wild how something so ordinary-white powder, like the stuff you dust your cookies with-can turn a whole ecosystem into a ghost town. we treat nature like a trash bin that doesn’t scream. but it does. it just does it slowly. like a sigh you don’t notice until you’re standing in the silence.

phenter mine

November 5, 2025 AT 07:01thx for this post i had no idea this was even a thing. just read about the sweden ban and wow that’s so cool they made it mandatory. maybe we need a law like that here too? i’ll share this with my city councilor :)

ps: typo in ‘reusue’ lol

Aditya Singh

November 6, 2025 AT 15:16you’re conflating bioavailability with toxicity. calcium carbonate is a buffer, not a poison. the heavy metals are negligible and anthropogenic inputs dwarf industrial waste. also, methane from landfills is primarily organic matter-this sludge is mineralized. your ‘22.5 million tons CO2’ is based on flawed lifecycle analysis ignoring the carbon sequestration potential of the original limestone. this is fearmongering dressed as environmentalism.

Katherine Reinarz

November 7, 2025 AT 10:12OMG I JUST REALIZED MY DAD’S COMPANY DUMPS THIS STUFF!!

he says it’s ‘just chalk’ but now I’m scared to visit his office… what if my kids get sick??

can someone DM me a list of labs that test this?? i need to know if my house is poisoned!!

also why isn’t this on the news??

John Kane

November 9, 2025 AT 05:05This is one of those topics that doesn’t get enough airtime because it’s not dramatic enough. No explosions. No oil slicks. Just silent soil. Quiet rivers. But the truth? It’s the quiet stuff that kills ecosystems over decades.

I’ve seen this firsthand in rural Queensland-farmers who thought their land was just ‘going bad’ didn’t realize it was the waste dump three miles downwind. The solution isn’t just tech-it’s community education. We need local workshops, school programs, maybe even citizen science kits to test soil pH. It’s not complicated. It just takes will.

Callum Breden

November 9, 2025 AT 22:30The entire premise is emotionally manipulative pseudoscience. You cite anecdotal crop yield reductions and infer causation without controlling for rainfall, fertilizer use, or crop rotation. The mercury levels cited are below WHO thresholds. The methane emissions are speculative and poorly sourced. This is not a crisis-it is a manufactured narrative designed to stoke fear and justify regulatory overreach. The real environmental crime is the misallocation of resources toward non-problems.

Mansi Gupta

November 11, 2025 AT 11:27Thank you for sharing this with such nuance. In India, we see similar issues with cement plant byproducts-often dumped near rivers under the assumption that ‘it’s just limestone.’ But the trace elements, combined with monsoon runoff, create slow poisoning of aquifers. What’s needed isn’t just policy, but cross-border knowledge sharing. Perhaps a global database of waste composition and reuse success stories? I’d be happy to help compile data from our region.

Erin Corcoran

November 12, 2025 AT 12:54soooo… if we can use this in cement and road bases, why aren’t we doing it everywhere?? 😅

my cousin works in construction and they’ve started using recycled scrubber residue in concrete-super cheap and it actually sets faster! 🤯

we need more of this. like, ASAP. #CircularEconomy #WasteIsAWrongWord

shivam mishra

November 13, 2025 AT 03:33Let’s be real-the real bottleneck isn’t technology, it’s bureaucracy. Even when a mill has a viable recycling plan, getting permits to reuse waste takes 18+ months because regulators treat it like radioactive material. Meanwhile, they’re fine with dumping it. We need standardized testing protocols and fast-track reuse certifications. I’ve worked with three Australian mills on this-same story every time. Red tape kills innovation.

Alex Hundert

November 14, 2025 AT 19:15And here’s the kicker: the companies that dump this waste are the same ones lobbying to keep it classified as non-hazardous. They’re saving millions on disposal costs while the public foots the bill in degraded land, lost agriculture, and cleanup later. It’s not just lazy-it’s predatory. We need to hold them accountable, not just regulate the waste.